Our story of one of the oldest furnace makers begins in 1922, when the General Machine Company produced an innovative Automatic Electric Furnace-Man Coal Stoker. (Fig. A) shows one of their earlier badges used during that time and (Fig B) shows what a furnace of theirs would look like from 1970. Before, homeowners would have to shovel heavy loads of coal into their furnace, but with EFM’s new approach those days were over. Here’s a short explanation on how that worked:

1. The Coal Hopper & Feeder

Instead of shoveling coal into the fire by hand, these furnaces had a storage bin called a hopper. A hopper held a supply of coal and used a small motor-driven device (called a stoker) to feed coal into the fire automatically. You just had to refill the hopper every day or two which meant no more constant shoveling.

2. Keeping the Fire Breathing

To keep the coal burning properly, the furnace needed air. That’s where the blower fan came in. It pushed air into the fire, like blowing on kindling to get a fire going. The more air, the hotter and cleaner the burn.

3. Heat When You Need It

Many of these systems were hooked up to a room thermostat. If the house got too cold, the thermostat would signal the furnace to feed in more coal and crank up the heat. Once the room warmed up, it would slow down or stop feeding coal — sort of like an early version of cruise control for home heating.

4. Ash Handling Made Easy

Burning coal creates ash, and with old systems, you had to shovel it out yourself. But these furnaces had a grate that could be shaken (by hand or by motor), which dropped the ashes into a pan below. All you had to do was empty the pan once in a while

(Fig. A)

(Fig. B)

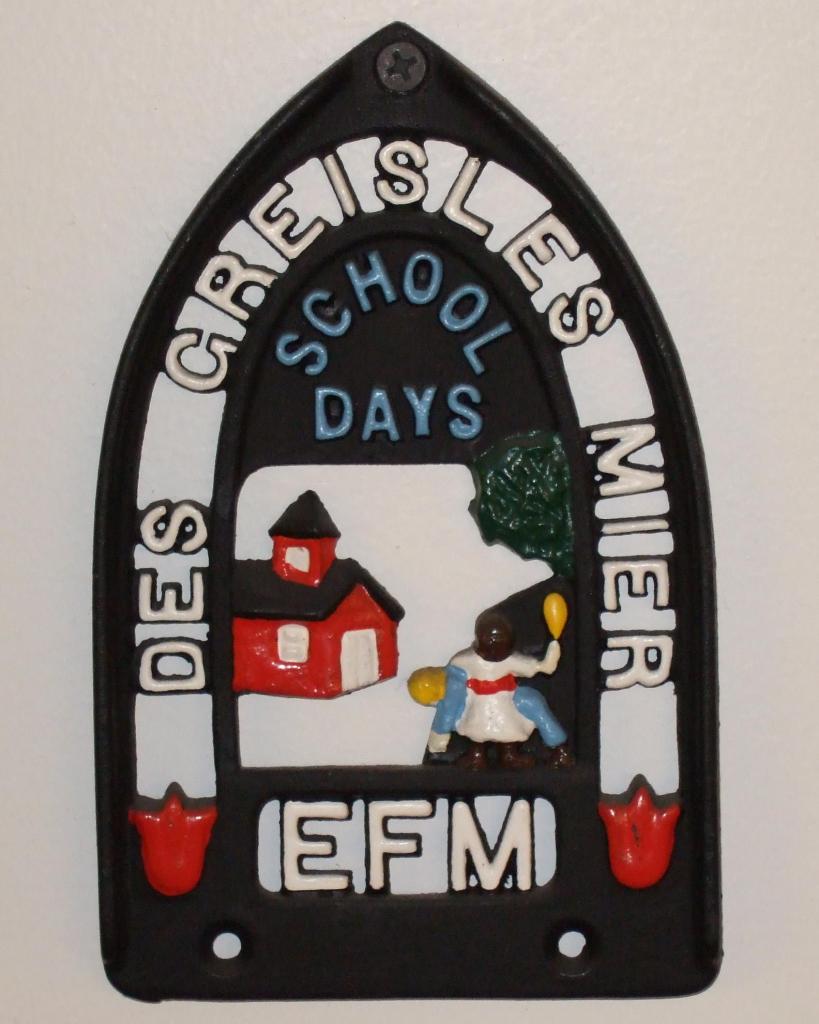

Following the company moving to Emmaus PA in the 1940’s and then a merger to Bellmont Industries in 1968, their design advertising had changed to (Fig. C). On many of their larger industrial boilers, they would use the emblem in (Fig. D) for those applications. Moving into the late 80’s they had transitioned over to using the hot rod style emblem that even today if you visit them they still have in use on (Fig. E). After a sale of the company in 1999, it is now known as EFM company that still to this day produces similar strong quality furnaces and boilers. In 1953, as part of a promotion for their employees and dealers, released trivets in the form of an ashtray as show in (Fig. F).

Fig. C

(Fig. D)

(Fig. E)

(Fig. F)

Following the advertising role that helped push EFM sales in their community with ornate designs of their emblems also brought Trivets which had been repurposed flatirons that had previously lost fashion in the 1940’s in laundries. These cone shaped flatirons had been made into ornate patterns that resembled the culture of the time in their community. Only 500 would be sold every year, beginning in 1953. (Fig. G) and (Fig. H) showcases some of the trivets of this brands past.

(Fig. G)

(Fig. H)

Leave a comment